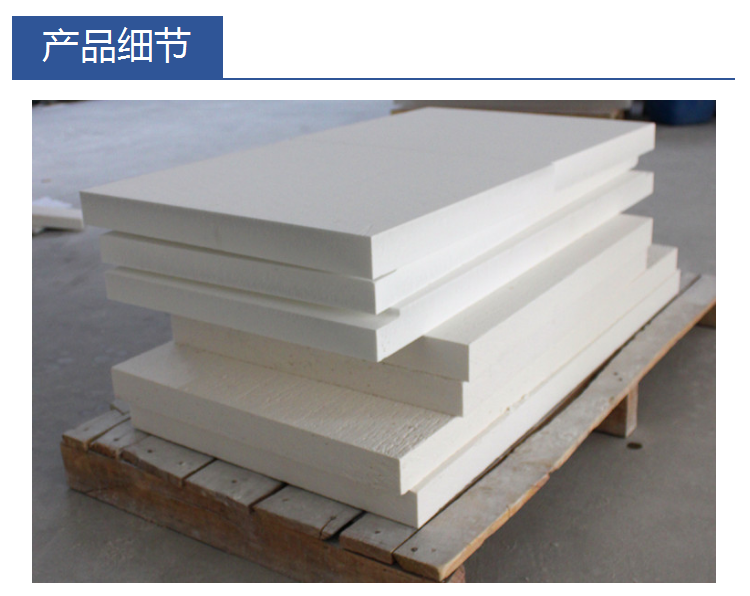

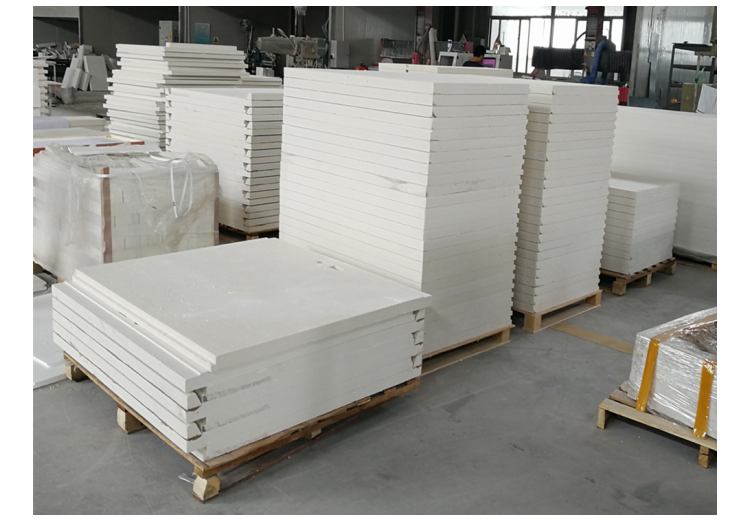

Aluminum Silicate Fiber Board / Ceramic Fiber Board

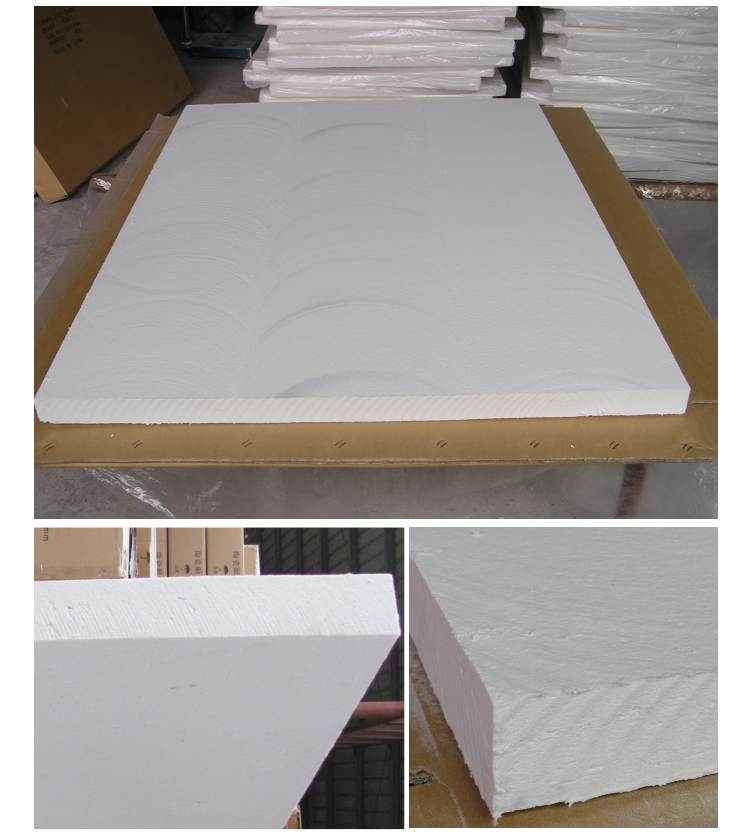

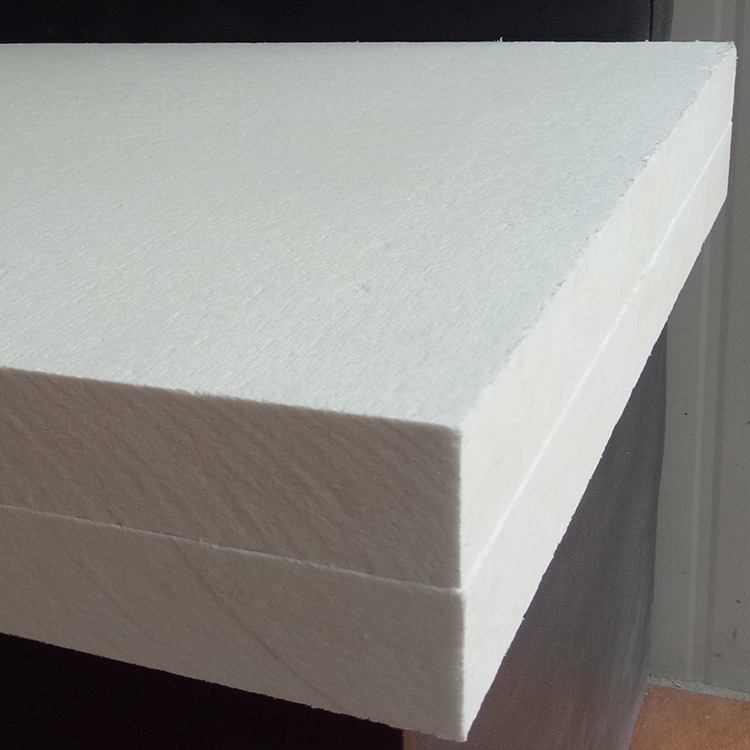

This product is used as fire partition of ceramic kiln and building materials kiln, to against the pollution of flame to the product. This product can be divided into more than four series of products according to different materials to meet the different temperature of working environment. The product's volume weight is between 200 to 350 Kg/m3. And it has the advantages of big volume weight, high strength and good effect of thermal erosion resistance.

Characteristics:

Low thermal conductivity

Low heat capacity

Excellent thermal stability and thermal shock resistance

High compressive strength and good toughness

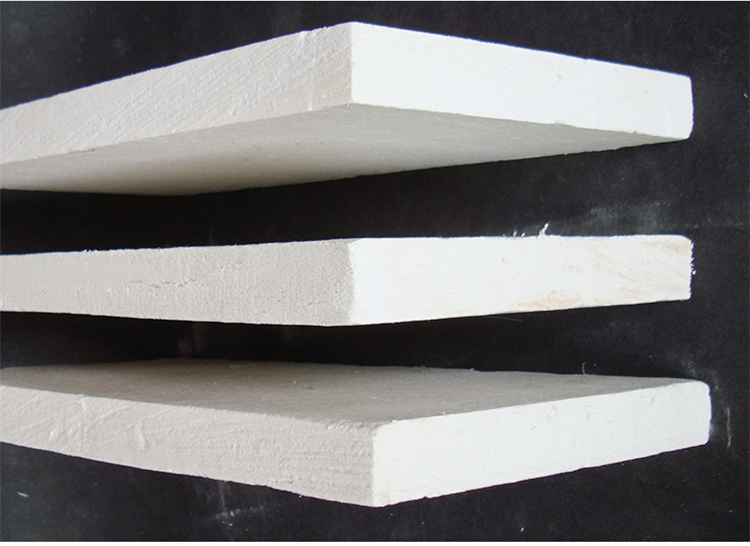

Technical Specification:

Bulk Density | 200-350(kg/m3) | product | Ceramic Fiber Board |

Size | 600*400*10-50(mm) 1200*600*10-50(mm) 1000*500/600*10-50(mm)

| Refractory Temperature | 1260(℃) |

Thermal Conductivity(w/m.k) | 0.035(℃) | ||

Application:

1. Cement kiln back lining heat preservation in building material industry, kiln door damper;

2. Petrochemical, metallurgy, ceramic, glass profession kiln stove back lining heat preservation;

3. Heat treatment furnace back lining heat preservation, industrial furnace wall lining, masonry insulation layer;

4. Non-ferrous metal profession back lining heat preservation;

5. High temperature reaction and heater equipment back lining heat heat insulation, High temperature machine insulation;

6. Sound insulation, heat insulation, fire insulation in aerospace, shipbuilding,