Carbon Fiber Felt

Introduction

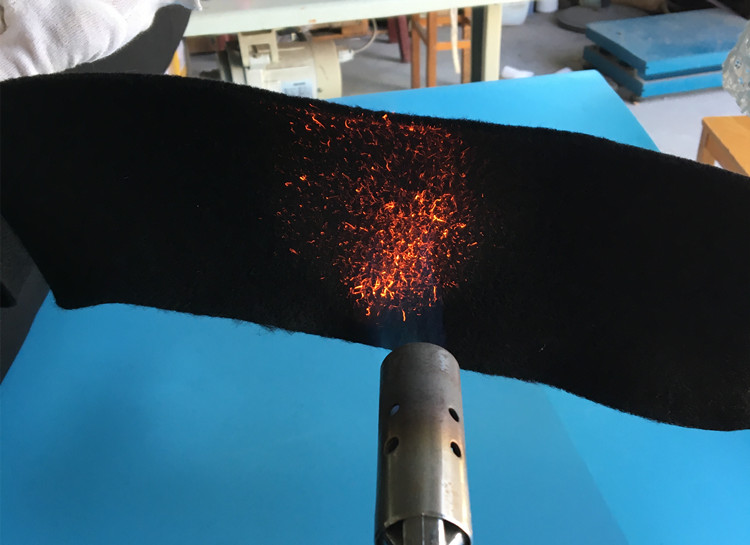

Carbon fiber felt has the performance of high temperature and fire prevention, widely used in various high temperature vacuum furnace for heat insulation, also can be made to carbon composites. Because 90% interspace of carbon fiber felt, it has superior heat insulation in vacuum or inert gas under high temperature environment, stable heat insulating performance, soft, small heat capacity, conveniently operation.

This product used PAN fiber as raw materials, needle felt, through oxidation, carbonization and graphitization etc, processed into high temperature and heat insulation material.

Specification

Unit | Pan Based Carbon Fiber Felt | Rayon Based Carbon Fiber Felt | |

Surface Area | 400~1350 g/m2 | 400~1350 g/m2 | |

Carbon Content | 90~95% | 90~95% | |

Tensile Strength | Warp-Wise | 8~14 | 8~14 |

Broad-Wise | 10~ 16 | 10~ 16 | |

Thermal Conductivity | <0.08 w/m.k | <0.08 w/m.k | |

Ash | 0.765% | 0.402% | |

Thickness | 3/6/10/12 mm | 3/6/10 mm | |

Width | Max:1000 mm-1200 | Max :1000 mm1200 | |

Length | Max:15000 mm | Max:15000 mm | |

Unit | Graphite Felt |

Surface Area | 600~1800 g/m2 |

Carbon Content | 99-99.5% |

Thermal Conductivity | <0.08 w/m.k |

Ash | 0.71% |

Thickness | 3/6/10/12 mm |

Width | Max :1000 Mm-1200mm |

Length | Max:15000 mm |

Note:

1. When the temperature exceeds 400 ℃, must use it in a protective atmosphere or inert gas.

2. Can be cut into any shape as required.

Application:

1. Used for thermal insulation: vacuum furnace, induction furnace, sintering furnace, etc.

2. Used for electric conduction: electrode.

3. Used for heating material: carbon fiber quartz heating tube.