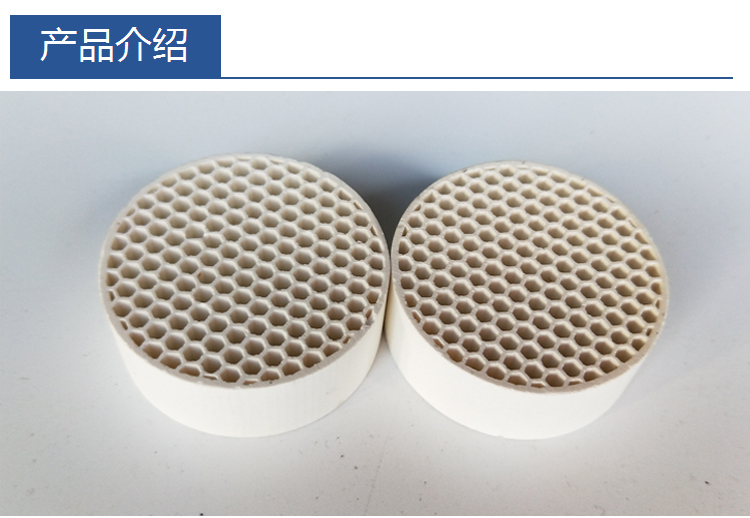

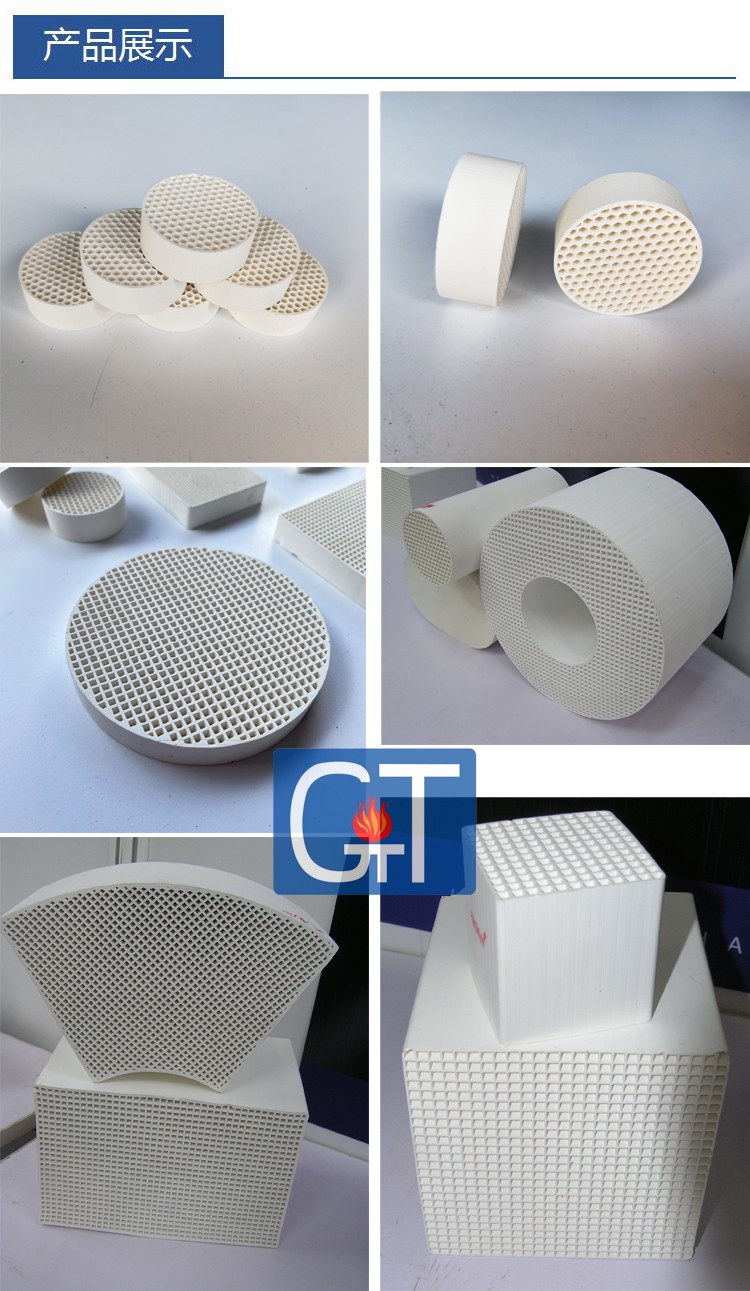

Honeycomb Ceramic Soldering Board / Honeycomb Ceramic Soldering Block / Honeycomb Soldering Board For Soldering Jewelry & Welding / Ceramic Honeycomb Catalytic Combustor

Honeycomb ceramic block, used in gas stove, refrigerator, oven gas cooker, automobile exhaust pipes, etc.

Characteristics

Honeycomb ceramics has large special surface area, heat capacity, low thermal expansion coefficient, good corrosion and heat resistance, used in chemical, metallurgical, gas, and environmental protection, etc.

Application

1. Chemical mass transfer stuffing large special surface area, making fluid distribute uniform, high separation efficiency.

2. Catalyst support lower the oxidizing temperature of organism, purify industrial waste gas.

3. Heat storage stuffing used for regenerative furnace, with large heat capacity and40-70%energy saving.

4. Fuel gas distributor balance heat distribution, promote complete combustion, with more than 10%energy saving.

5. Refractory kiln small piled weight, fast heat transferring, high thermal efficiency.

Technical property

Item | Alumina Porcelain | Mulite Porcelain | Cordierite Porcelain | Mulite-Cordierite Porcelain | |

Chemical Composition(%) | Al2O3 | 48-55 | 66-72 | 32-36 | 55-65 |

SiO2 | 40-45 | 25-30 | 45-52 | 28-36 | |

MgO | 5-8 | 2.5-3.2 | |||

Density(g/m³) | 2.7 | 2.9 | 2.4-2.6 | 2.9-3.2 | |

Shock Resistance(℃) | ≥150 | ≥350 | ≥250 | ≥250 | |

Maximum Service Temp(℃) | 1300 | 1600 | 1300 | 1400 | |

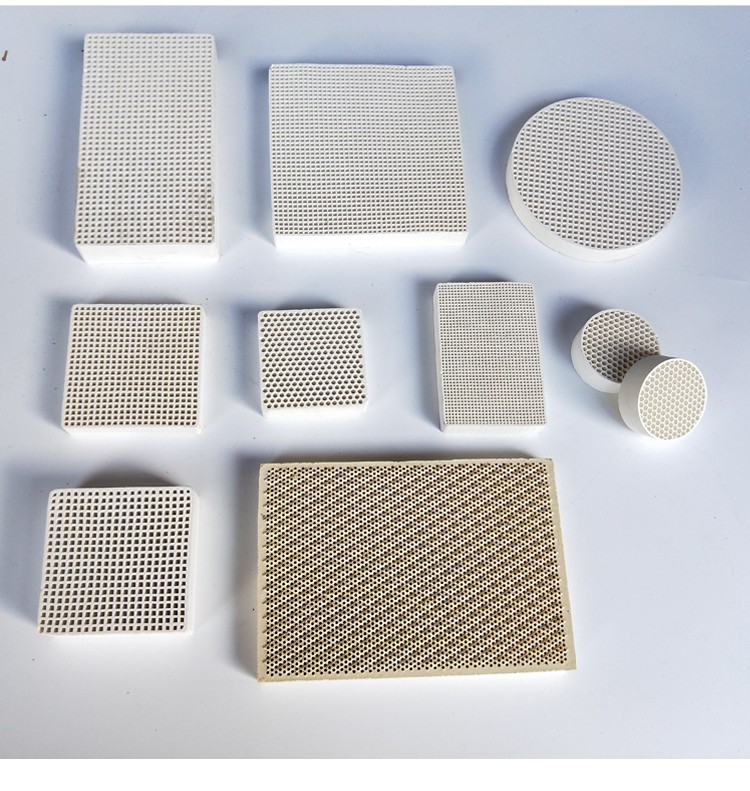

Size: 50 x 50, 40 x 40, 65 x 65, 50 x 75, Φ90, Φ110, Φ120, etc.

It can customized according to customer requirements .

Hole shape: square, circle, triangle, hexagon, etc.

Hole number: 100 cis(the number of holes per square inch), and other series 200, 300, 400cis.